TL;DR

- Account for full project timeline and disruptions

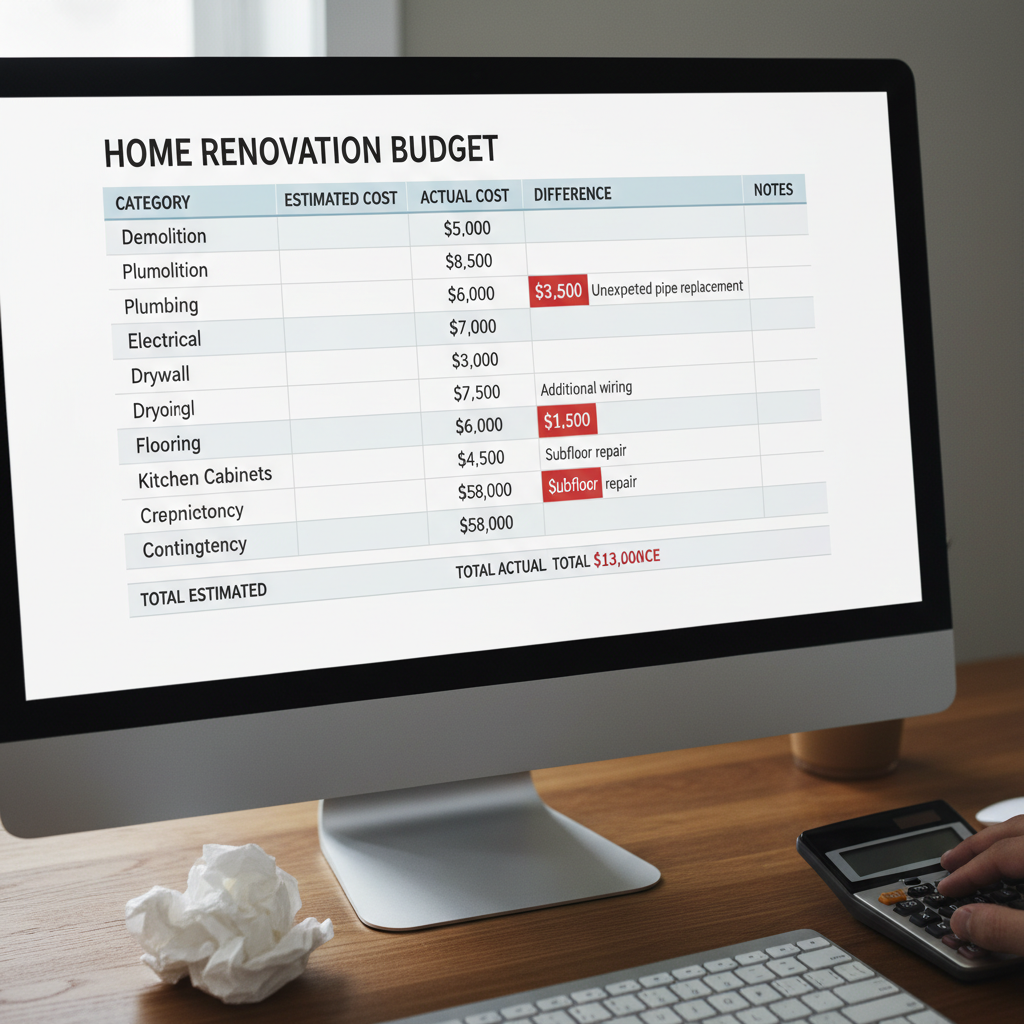

- Budget for all costs, including unexpected ones

- Assess compatibility with existing setup

- Prepare thoroughly for installation day

Upgrading kitchen countertops seems like a straightforward project, but many homeowners encounter unexpected challenges that lead to delays, extra costs, or unsatisfactory results. As a renovation expert, I’ve seen the consequences of inadequate planning and overlooked details. Understanding common pitfalls helps you execute a smooth countertop upgrade that enhances your kitchen.

Common errors range from timeline mismanagement to compatibility issues, resulting in extended disruptions or costly corrections. By avoiding these mistakes, you ensure your upgrade project delivers the desired improvements without unnecessary stress. Let’s examine the most frequent issues and how to prevent them.

Underestimating Project Timeline

One of the biggest mistakes is poor timeline planning.

Manufacturing Delays

Not accounting for material production time.

- Custom Orders: Special colors or patterns take weeks

- Supplier Backlogs: Popular materials have waiting lists

- Quality Control: Time needed for fabrication and inspection

- Shipping Time: Transportation from manufacturer to installer

Installation Scheduling

Failing to coordinate all project phases.

- Preparation Time: Site preparation before installation

- Curing Periods: Adhesive and sealant drying time

- Weather Dependencies: Some installations require specific conditions

- Multi-Trade Coordination: Plumbing and electrical work timing

Ignoring Disruption to Daily Life

Not preparing for kitchen unavailability.

Meal Planning Oversights

Failing to arrange alternative cooking solutions.

- Temporary Kitchen: Setup costs and space requirements

- Meal Services: Restaurant meals or meal kit expenses

- Storage Solutions: Food preservation during disruption

- Family Coordination: Managing schedules around project

Daily Routine Disruptions

Underestimating impact on household activities.

- Hygiene Issues: Limited access to sinks and bathrooms

- Work-from-Home: Managing remote work without kitchen access

- Guest Accommodations: Handling visitors during renovation

- Pet Care: Food and water access for animals

Failing to Budget for Hidden Costs

Unexpected expenses that inflate project costs.

Discovery Issues

Unforeseen problems revealed during demolition.

- Structural Problems: Foundation or framing issues

- Plumbing Complications: Hidden pipe repairs needed

- Electrical Updates: Outdated wiring requiring replacement

- Pest Infestations: Problems discovered during removal

Material Waste and Changes

Additional costs from mistakes or changes.

- Cut Errors: Material waste from measurement mistakes

- Design Changes: Mid-project modifications

- Quality Upgrades: Deciding to upgrade during installation

- Shipping Damage: Replacement costs for damaged materials

Choosing Incompatible Materials

Selecting countertops that don’t work with existing elements.

Size and Weight Issues

Materials that exceed structural capacity.

- Support Requirements: Additional framing for heavy materials

- Load Bearing: Cabinet strength for material weight

- Foundation Impact: Heavy materials affecting house structure

- Transportation: Access limitations for large pieces

Style Conflicts

Materials that clash with current kitchen design.

- Color Mismatches: Countertops that don’t complement cabinets

- Finish Inconsistencies: Texture conflicts with existing surfaces

- Era Conflicts: Modern materials in traditional kitchens

- Lighting Effects: Materials that look different in kitchen lighting

Skipping Professional Assessment

Not consulting experts before starting.

Structural Evaluation

Missing important load and support requirements.

- Cabinet Inspection: Strength assessment for new materials

- Plumbing Check: Water line capacity and pressure testing

- Electrical Assessment: Circuit adequacy for kitchen appliances

- Ventilation Review: Range hood compatibility and airflow

Design Consultation

Failing to get professional design input.

- Workflow Analysis: Optimizing kitchen efficiency

- Ergonomics Review: Proper heights and reach requirements

- Lighting Planning: Task and ambient lighting design

- Storage Optimization: Maximizing cabinet and drawer space

Not Preparing for Installation

Inadequate site preparation causing delays.

Workspace Clearing

Failing to properly empty and protect the area.

- Appliance Removal: Professional disconnection and storage

- Cabinet Emptying: Complete removal of contents

- Floor Protection: Preventing damage to flooring

- Access Planning: Clear pathways for workers and materials

Utility Management

Not handling essential services properly.

- Temporary Plumbing: Portable sinks and water access

- Power Solutions: Generators or extension cord setups

- Internet Access: WiFi for project management apps

- Security Measures: Protecting site during off-hours

Overlooking Permits and Regulations

Missing required legal approvals.

Building Permits

Local requirements for structural changes.

- Load Bearing Changes: Permits for additional support

- Plumbing Modifications: Approvals for water line changes

- Electrical Updates: Permits for new circuits or outlets

- Zoning Compliance: Restrictions on home modifications

HOA Restrictions

Community association rules and guidelines.

- Design Standards: Approved colors and materials

- Exterior Impact: Rules affecting visible changes

- Noise Ordinances: Work hour restrictions

- Contractor Requirements: Approved vendor lists

Rushing Material Selection

Making hasty decisions under pressure.

Comparison Shopping

Not thoroughly researching options.

- Quality Differences: Understanding material performance

- Warranty Variations: Coverage differences between brands

- Supplier Reputation: Track record and customer service

- Return Policies: Options if materials don’t meet expectations

Sample Testing

Not properly evaluating materials.

- Real Conditions: Testing in actual kitchen lighting

- Wear Simulation: Understanding long-term appearance

- Maintenance Requirements: Care commitment assessment

- Family Feedback: Getting input from all household members

Ignoring Existing Plumbing/Electrical

Failing to assess current utility systems.

Plumbing Compatibility

Existing water systems may need upgrades.

- Pressure Requirements: Adequate water pressure for fixtures

- Pipe Materials: Compatibility with new plumbing

- Drainage Capacity: Sufficient flow for larger sinks

- Filtration Systems: Integration with water treatment

Electrical Capacity

Power systems may require enhancement.

- Circuit Upgrades: Additional circuits for appliances

- GFCI Requirements: Ground fault protection near water

- Smart Integration: Wiring for modern appliances

- Outlet Placement: Proper positioning for kitchen use

Forgetting Post-Installation Care

Not planning for the period after installation.

Initial Maintenance

Immediate care requirements for new surfaces.

- Sealing Schedule: Protecting porous materials

- Cleaning Protocols: Proper initial cleaning procedures

- Usage Restrictions: Limiting heavy use initially

- Monitoring Period: Watching for settling or movement

Warranty Activation

Ensuring protection for your investment.

- Registration Requirements: Activating manufacturer warranties

- Inspection Documentation: Photos and records for claims

- Care Instructions: Understanding maintenance requirements

- Service Contacts: Saving installer and supplier information

Conclusion

Avoiding common pitfalls when upgrading kitchen countertops ensures a successful renovation project. As your kitchen upgrade resource, I recommend accounting for full timelines, budgeting comprehensively, assessing compatibility, and preparing thoroughly. By addressing these key areas, you’ll achieve the beautiful, functional kitchen countertops you envision.

Use our directory to find experienced countertop upgrade specialists with proven track records. With proper planning and execution, your countertop upgrade will transform your kitchen into the space you’ve always wanted.